|

High Performance Ford vehicles that run distributor-less ignitions have EDIS electronics. Many people are unaware of EDIS and don't know much about it. EDIS comes into play when a racer starts getting serious about their vehicle.

EDIS's 2 main functions are generating PIP and SPROUT signals to the engine management system. In a nutshell the module gets a crank trigger and position signal from the trigger wheel and then the EDIS-8 module organizes the firing order and triggers the coil packs in the proper order. Itís considered a "waste spark system" meaning that it fires at compression and exhaust strokes near TDC. As long as you organize the wires accordingly, it could conceivably run any firing order you want on a typical 4-6 or 8 cylinder. The EDIS-8 unit puts out a PIP signal, which is what most fuel injection systems use to trigger the injectors and simply determines how fast the engine is rotating. It then has a SAW wire (Spark angle width) also know as the spout, this is the signal that tells the EDIS module what to do for timing.

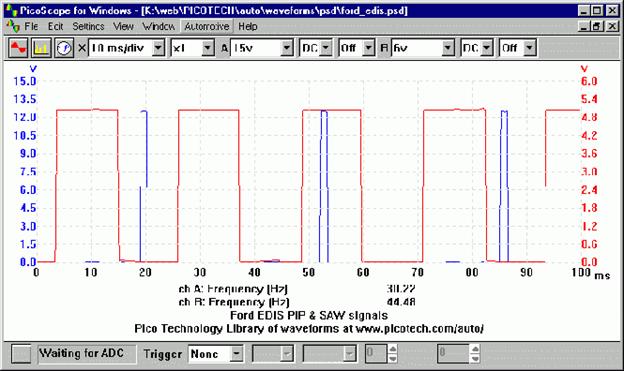

Profile Ignition Pick-up is the term used for the signal sent from the (EDIS) to the (ECM). This signal is the digitally modified signal that originated from the Crank Angle Sensor (CAS) in an Alternating Current (AC) format. The PIP signal into the ECM is a squarewave switched at 12 volts and is the ECM's reference for the engines speed and position. The PIP signal when received by the ECM can then be modified to take into account the ignitions timing advance. This returning signal to the EDIS unit is called the SAW signal as is in the form of a 5 volt squarewave. Both signals can be seen in the example waveform with the PIP signal in blue and the SAW signal in red.

The Ford EDIS system is an enhanced version of the DIS ignition system. The major difference is that the DIS system requires a CID (Cylinder Identification; cam phase) sensor in addition to the crank driven toothed wheel. The EDIS system only requires a 36-1 toothed wheel and VRS (Variable Reluctance Sensor) crank sensor.

The EDIS system is comprised of an EDIS module, crank wheel, crank sensor, and coil packs. This system is completely standalone and will properly ignite 4, 6, and 8 cylinder engines using the wasted spark method. The system relies on the ECU (Electronic Control Unit) to control spark timing, but will function if no ECU is connected. Spark Angle Word (SAW) is the response by the control module to the EDIS module after the control module does its usual job of calculating the advance or retard of spark timing. In EDIS, SAW is the same kind of signal as SPOUT is to TFI-IV and DIS. In the EDIS Module, the microprocessor decides which coil to fire at what millisecond -- coil selection and spark timing. In addition to the coil-driver outputs, the EDIS Module confirms

its timing by sending the IDM signal to the control module, a signal that also operates the tachometer.

The downfall of the stock EDIS module is that it was never intended for higher RPM applications, because it was designed for powerplants with a 6500 redline. EDIS started in the early 90's and was used in Lincoln Mark VIII or Lincoln Towncar application where they used EEC IV Generation computers with distributor-less ignition. Fast forward to 1996 and the introduction to EEC V OBD II computers, the EDIS electronics are built into the computers electronics. EEC V computers did not have the need for a separate device. When racing maniac's such as myself with distributor-less ignitions ditch the factory computer, you need to use a separate box that will generate PIP and SPROUT signals to the engine management system that one decides to purchase (Speed Pro, Gen VII or EPEC).

What racers did (including myself, Lideo, Tim Palmer, Reggie etc) was use an EDIS box out of a Lincoln Mark VIII (the only one sold by Ford). The downside was that once Engine RPM'S reached 8000 rpms, the PIP signal attenuates to the point that Speed Pro would not recognize it and "guess "In real time". On my datalogger once 8000 rpms would be achieved the datalogged RPMS would show something like this (2500, 6200, 4740,3954, 7000, 5400). This erratic change in RPM would cause the car to misfire and basically simulate spark blowout.

Forward to Mid 2001. FAST (Fuel Air Spark Technology), the company that now owns Speed Pro came out with their own EDIS module. In order to use the new FAST box, (http://www.fuelairspark.com/Information/WhatsNew/Press/30-5000_30-5001.pdf) you have to run sequential injection (an upgrade needed on Speed PRO users that run Batch Fire) because it needs to see an input from the cam position sensor (Batch fire doesn't use cam position sensor). Using the FAST EDIS also requires using a magnetic crank trigger wheel and pickup that must be bolted on the crankshaft pulley. The stock crank trigger wheel and pickup can no longer be used. Once these upgrades are complete, the problems associated with the EDIS box itself are eliminated.

Also around the same time the new EDIS box came out, MSD came out with a HO version of the DIS 4 box that has been so popular. The HO model produces an incredible 170 milliJoules of spark energy with 470 volts going to the coil packs. This is up from 115 milliJoules in the standard DIS-4 box and more energy than an MSD 7AL-2 or 7AL-3. Therefore any limitations with EDIS ignition should be in the coilpacks themselves (yet to be tested). A few companies make aftermarket coilpacks such as Accel and MSD but they are only "slightly" higher in output. I'm hoping that the stock coil packs will not be a limitation. Ford uses EDIS in Indy car technology so I think they will be fine.

Coil packs versus Coil on plugs

It is my feeling that Coil packs will support more horsepower. It is still is unanswered as to how much horsepower either system will support. The reason I say this is because Tim Palmer has made the most horsepower so far with coil packs at around 1100 bhp. But he only did that for a very short time. Nobody has really made over 1000 bhp with coil on plugs (at least from what I am aware of) With Bob Trinanes and myself both going back to coil packs, we will find out that answer.

Other alternatives to EDIS

Randy and JR took another approach. They used a MSD distributor that could be mounted like an alternator, and be driven off of crankshaft rpms. This allowed them to ditch the EDIS and DIS all together and use a 7AL box.

Some Photos Courtesy of JMS Chip & Alternative Auto.

|